As the world advances toward carbon neutrality and green transformation, materials science is undergoing a profound revolution. Traditional materials face numerous challenges in terms of performance, environmental impact, and resource sustainability. In response, a new generation of eco-friendly materials has emerged. Among them, basalt fiber is rapidly gaining traction as a key enabler of green manufacturing and sustainable development, thanks to its outstanding comprehensive performance and environmentally sustainable properties. What is Basalt Fiber? Basalt fiber is an inorganic, non-metallic material made by melting natural basalt rock at high temperatures and drawing it into continuous fibers. No chemical additives are used during the production process, making it closer to “physical manufacturing.” This gives it a distinct environmental advantage over traditional composite materials such as carbon fiber and glass fiber. As a Professional Composite Materials Supplier Green Advantages: Building a Sustainable Composite Production System Natural Raw Materials, Abundant Resources Basalt is a naturally abundant rock that does not rely on petroleum-based resources, avoiding resource bottlenecks and aligning with the global trend toward material transition. Eco-Friendly Manufacturing, Clean Process

current location : home

Riding the Green Wave The Rise of Basalt Fiber in Sustainable Materials

Test

Table of Contents

Quick Takeaway:

Visual effect, stability and energy consumption are the key points in

usage of led display. And when we do the inspection, it can mainly be

divided into 5 categories.

- Order information compliant with PI

- Appearance Check before power up

- Screen Splicing Check

- Function Check after power up

- Stability Check

Reference Documents:

- SJ/T 11141-2017 Generic Specification for LED displays

- SJ/T 11281-2017 Measure Methods of light emitting diode (LED) displays

- GB/T 43770-2024 Specification for Indoor LED displays

Order information compliant with PI

When you place a order, you would have a specs detail that offered by

your supplier, Hence the first thing in inspect the led display is to

check if the materials used in the order is compliant with the PI.

Important components like LED lamps, ICs and Power suppliers not only

affect the price of the led display a lot, but also affect the quality a

lot.

Appearance Check before power up

Appearance check before power up is mainly focus on appearance flaws,

Such as

- Scratches

- Burrs or Broken parts

- Missing or loosing Screws, Safety cables

- Labels

- Panel's color uniformity check

Screen Splicing Check

- Splicing gaps check

- Splicing evenness check

- Screen color uniformity

- All electric socket integrity

- Connection plate integrity and rigidity

Function Check after power up

Function check is the most important check of all, as this determine the

visual effect of the led display. Normally for the function check, we

need to let the led display warm up first.

Stability Check

- Power off test

- Waterproof Checking

- Shaking testing

- Fire Resistant testing

- Certificates requirements

...

The Origin and Evolution of Full-Face Motorcycle Helmets

The design and material selection of full-face motorcycle helmets have gone through years of development, originating from the increasing focus on motorcycle rider safety. From the earliest simple helmets to today’s complex full-face designs, it has undergone numerous technological innovations and continuous refinement. Below, we will review the origin and evolution of full-face motorcycle helmets and understand how this equipment has become safer and more comfortable over time. The history of motorcycle helmets can be traced back to the early 20th century when motorcycles were just entering the mass market. The earliest motorcycle helmets were mainly made of leather and metal materials, primarily to protect the rider's head from minor impacts and wind or dust. While these early helmets provided some protection, they were far from sufficient for the demands of high-speed riding. As motorcycle speeds increased, the need for better head protection grew. By the 1940s, motorcycle racing and road riding had become more popular, and helmet safety became a growing concern. Helmet designs gradually moved towards more comprehensive protection. The concept of the full-face motorcycle helmet emerged in the 1960s. At that time, helmets generally only covered the top of the head and did not protect the chin or face. However, with the increasing popularity of motorcycle racing and high-speed road riding, the need for better head protection became urgent, leading to the evolution of helmet designs. By the late 1960s, the motorcycle racing community began demanding higher levels of safety for helmets, giving rise to the full-face motorcycle helmet With the development of the motorcycle industry, the materials used for helmets underwent significant innovations. Early full-face helmets were typically made of metal and plastic, but these materials were heavy and offered limited impact resistance. In order to improve protection and reduce weight, manufacturers began introducing more advanced materials. In the 1980s, fiberglass and polycarbonate materials began to be used in the outer shell of motorcycle helmets. These materials offered better strength and lighter weight compared to traditional metals, greatly improving the protection and comfort of the helmets.

1. Early Development of Motorcycle Helmets

2. The Birth of Full-Face Helmets

3. Material Innovations: From Traditional Materials to Carbon Fiber and Composites

The Safety Protection Principle of Carbon Fiber Helmets How Innovative Materials Protect Riders

In high-speed riding, extreme sports, or daily commuting, helmets are crucial protective gear for head safety. With the rapid advancement of materials science, traditional plastic or metal helmets are gradually being replaced by high-performance composite materials 1. The Molecular Structure of Carbon Fiber: Analyzing Protective Advantages at the Micro Level The basic unit of carbon fiber is composed of carbon atom crystals with diameters of only 5-10 micrometers. It forms a layered structure through high-temperature carbonization and resin curing. This molecular design gives carbon fiber several essential performance features: High Strength-to-Weight Ratio: Anisotropic Toughness: Excellent Fatigue Resistance: Engineer’s Explanation “The protective design concept of carbon fiber helmets is to absorb impact through ‘softening the hard’ approach. When a collision occurs, the material undergoes controllable deformation to gradually disperse the impact force. At the same time, the internal honeycomb structure acts like a spring, cushioning in stages, ultimately controlling the impact force within a safe threshold that the human body can withstand.” 2. The "Triple Protection Design" of Carbon Fiber Helmets Based on the unique properties of carbon fiber, the protective design of carbon fiber helmets can be divided into three key layers: Outer Shell Layer: Cushioning Layer: Inner Lining Layer: Case Comparison In a 50 kmhttps://www.basaltmssolutions.comh impact test, traditional ABS plastic helmets transmit the impact force to the head, with test results showing the force can reach up to 250G, exceeding the safety threshold (200G). In contrast, under the same conditions, the carbon fiber helmet's impact force is only 180G, and the outer shell remains intact, with the cushioning layer recovering 70% of its deformation. 3. Additional Advantages of Carbon Fiber Helmets Beyond excellent safety performance, carbon fiber helmets also offer several other notable advantages: Lightweight Design Carbon fiber helmets weigh only 280-350g, significantly reducing the neck strain compared to traditional helmets (450-600g). This is especially beneficial for long-duration rides, such as road racing and mountain biking. Aerodynamic Optimization Due to the high plasticity of carbon fiber, helmets can be designed with complex curved shapes, significantly reducing wind resistance. Professional team tests have shown that carbon fiber helmets save about 5% of energy expenditure at a speed of 40 kmhttps://www.basaltmssolutions.comh. Environmental Sustainability Basaltmssolutions uses innovative thermoplastic carbon fiber recycling technology, where old helmets can be disassembled and remade into sports equipment parts, reducing resource waste and promoting sustainable development. 4. Future Trends of Carbon Fiber Helmets With continuous technological advancements, the application of carbon fiber helmets is expanding: Intelligent Integration Due to the weak electromagnetic shielding of carbon fiber, helmets can easily integrate sensors to monitor impact data in real-time, providing potential risk alerts through mobile apps. Cross-Industry Applications Carbon fiber materials perform excellently not only in bicycle helmets but also in motorcycle helmets, firefighter helmets, and other fields, thanks to their lightweight and high-temperature resistance (some models can withstand short-term high temperatures of up to 300°C). Cost Democratization With the continuous optimization of production processes (such as automated filament winding technology), the cost of carbon fiber helmets has significantly decreased from the original tens of thousands of RMB to 2000-5000 RMB, making them increasingly accessible to the general public. 5. How to Properly Choose and Maintain Carbon Fiber Helmets? Selection Tips: Choose helmets with EN 1078, CPSC, or MIPS certification to ensure compliance with international safety standards. Check if the helmet lining is removable and washable, and whether the ventilation holes are integrated with the carbon fiber layer to avoid weak bonding points. Maintenance Do's and Don'ts: Avoid exposing the helmet to organic solvents like acetone, as they can corrode the resin coating. Even if the helmet appears intact, it should be replaced after a collision, as the internal structure may have been damaged. Carbon fiber helmets not only represent the latest advancements in materials science but also show deep concern for the rider's safety. Basaltmssolutions, as a professional composite materials supplier

Wholesale High-Quality Motorcycle Helmets Customization for Unisex Riders

When it comes to motorcycle safety and style, nothing is more important than a high-quality helmet. For riders who seek both protection and aesthetics, high-quality motorcycle helmets are a must-have. Whether you are a retailer looking for wholesale high-quality motorcycle helmets Why Choose High-Quality Motorcycle Helmets? Safety First: Customization Options: Unisex Design: The Role of a High-Quality Motorcycle Helmet Factory A reliable high-quality motorcycle helmet factory plays a crucial role in delivering top-tier products. Here are some key points to consider: Advanced Manufacturing: Customization Capabilities: Wholesale Expertise:

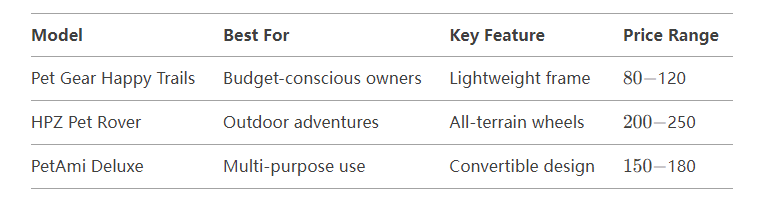

Can You Bring Your Dog to Walmart in a Stroller? A Guide to Dog-Friendly Stores

Taking your furry friend along for errands can be tempting, but store policies about pets vary widely. If you’re wondering, “Can I bring my dog to Walmart in a stroller?” or which retailers welcome pets, this guide breaks down the rules for popular stores like Walmart, Target, Tractor Supply, Home Depot, and Lowe’s.

1. Walmart: Service Animals Only (No Pets in Strollers)

Walmart’s policy is clear: only ADA-defined service dogs are allowed inside stores. Pets, emotional support animals, and dogs in strollers or carriers are not permitted, even if they’re well-behaved. Employees may ask:

-

“Is this a service animal?”

-

“What task is it trained to perform?”

Why? Health codes (especially in stores with groceries) and liability concerns drive this rule.

Alternatives: Use Walmart’s curbside pickup to shop without leaving your pup in the car.

2. Target: Similar to Walmart

Target follows a nearly identical policy: service dogs only. Pets in strollers, carriers, or leashed are not allowed unless they’re trained service animals.

Tip: Check Target’s website for local exceptions, but assume most locations enforce this strictly.

3. Tractor Supply: Dog-Friendly Haven

Tractor Supply is famously pet-friendly! Leashed dogs (and even cats!) are welcome in most locations. Some stores host “Pet Nights” with treats and events.

Rules:

-

Keep dogs leashed.

-

Clean up accidents promptly.

-

Verify with your local store first.

4. Home Depot: Generally Welcoming

Most Home Depot stores allow leashed, well-behaved dogs, though policies can vary by location. Many associates are pet lovers and may offer treats!

Check First: Call your local store to confirm. Avoid busy hours if your dog gets stressed.

5. Lowe’s: Dog-Friendly (With Caveats)

Like Home Depot, Lowe’s often welcomes leashed pets at managers’ discretion. Some locations even provide water bowls.

Pro Tip: Avoid bringing dogs near heavy machinery or crowded aisles for safety.

General Rules for Dog-Friendly Shopping

-

Call Ahead: Policies can vary by store, even within chains.

-

Leash and Clean Up: Even in dog-friendly stores, keep your pet secure and tidy.

-

Respect Boundaries: Avoid stores with strict “service animals only” rules (e.g., Walmart, Target).

-

Prioritize Safety: If your dog is anxious or reactive, skip the trip.

Dog-Friendly Alternatives

If Walmart or Target isn’t an option, try:

-

Pet stores (Petco, PetSmart, local shops).

-

Outdoor retailers (Bass Pro Shops, REI).

-

Farm supply stores (Tractor Supply, Rural King).

Final Thoughts

While a dog stroller might seem like a workaround for Walmart, sticking to pet-friendly stores ensures a stress-free experience for you, your pup, and store staff. Always prioritize training, safety, and respect for store policies—happy shopping!

Keywords: dog stroller in Walmart, dog-friendly stores, are dogs allowed in Target, is Tractor Supply dog friendly, are dogs allowed in Home Depot, is Lowe’s dog friendly.

🐾 Have a favorite dog-friendly store? Share it in the comments! 🐾

...The Best Dog Stroller for 2 Large Dogs – Why the PC408 Is a Game-Changer

Traveling with two big dogs? Whether your pups are seniors, recovering from surgery, or just love a comfy ride, a sturdy dog stroller for 2 large dogs makes outings easier. The PC408 Pet Stroller is built for durability, convenience, and comfort—here’s why it’s worth considering.

What to Look for in a Double Dog Stroller

Before buying, pet owners should consider:

✔ Size & Weight Capacity – Must fit two large breeds (e.g., Labradors, German Shepherds).

✔ Ease of Use – Folding, storage, and accessibility matter.

✔ Durability – Strong frame, tough fabric, and smooth-rolling wheels.

✔ Comfort – Padded, breathable, and easy to clean.

The PC408 checks all these boxes—let’s break it down.

PC408 Dog Stroller: Key Features

1. Roomy Enough for Two Big Dogs

Cabin dimensions: 87cm long × 50cm wide × 66cm tall

Max weight limit: 60kg (about 2 medium/large dogs)

Foldable design: Shrinks to 96cm × 24cm × 59cm for storage

Why it matters: Unlike flimsy strollers, this one actually fits two adult dogs comfortably. The removable padded mat has side bolsters for extra support, and the anti-slip base keeps them steady.

2. No More Zipper Struggles – Quick-Release Buckle

Many pet strollers use zippers, which can snag fur or break. The PC408 has a one-click plastic buckle—faster to open and close, especially with excited dogs.

3. Built-In Ramp for Easy Loading

Big dogs don’t always jump in easily. The rear ramp lets them walk right in, and the cover doubles as a storage pocket for leashes or treats.

4. One-Second Folding (Really)

Ever fought with a collapsing stroller? This one folds flat in seconds—no complicated steps. Great for car trips or small apartments.

5. Wheels That Handle Rough Ground

-

Front wheels: 8-inch EVA foam (quiet & smooth)

-

Back wheels: 11-inch treaded tires (stable on grass, gravel, or pavement)

Bonus: The top mesh panel unzips halfway, so your dogs get fresh air without escaping.

Who’s This Stroller Best For?

✅ Senior or injured dogs – Gives them a break from walking.

✅ Double-dog households – No more juggling two leashes while pushing a stroller.

✅ City pet owners – Maneuvers well on sidewalks and fits in tight spaces when folded.

✅ Travelers – Folds compactly for car trips or vet visits.

Real Downsides to Consider

-

Weight: At 14.6kg, it’s not ultra-light—best for frequent use, not hiking.

-

Assembly: Some users report minor setup needed (attaching wheels).

Final Verdict: Worth It for Big-Dog Owners

If you need a no-fuss, heavy-duty stroller for two large dogs, the PC408 delivers. The ramp, quick-fold design, and sturdy wheels make it a practical choice over cheaper models that wobble or wear out fast.

...The Complete Guide to Cat Strollers Benefits, Training Tips & Safety Advice

For many cat owners, the idea of walking their feline friend in a cat stroller seems like the perfect compromise between safety and outdoor enrichment. But do cats like strollers? The answer isn't simple - while some felines adore their rolling chariots, others may need convincing. This comprehensive guide will help you determine if a stroller is right for your cat and how to make the experience enjoyable for both of you.

Why Consider a Cat Stroller? Key Benefits Explained

Cat strollers offer numerous advantages that go beyond just being adorable:

Safe Outdoor Adventures

Unlike leash walking, strollers provide complete protection from traffic, aggressive dogs, and potential predators while still allowing your cat to enjoy fresh air.

Mental Stimulation

New research from the Journal of Feline Medicine and Surgery shows that controlled outdoor exposure significantly reduces stress and boredom in indoor cats.

Special Needs Solution

Perfect for:

- Senior cats with mobility issues

- Disabled felines

- Post-surgical recovery

- Anxious cats who resist harnesses

Travel Made Easy

Strollers transform stressful vet visits into calm outings and make pet-friendly vacations more manageable.

Reading Your Cat's Stroller Reactions

Understanding feline body language is crucial when introducing a stroller:

Positive Signs

- Forward-pointing ears and relaxed whiskers

- Curious sniffing and environmental scanning

- Content purring or kneading behavior

- Voluntary entry into the stroller

Stress Indicators

- Flattened ears or dilated pupils

- Excessive vocalization or panting

- Attempts to escape or hide

- Low crouching posture with tucked tail

Pro Tip:

Start with 5-minute indoor sessions before progressing to outdoor walks. Always let your cat set the pace.

Step-by-Step Cat Stroller Training Guide

1: Familiarization (Days 1-3)

- Place the open stroller in your cat's favorite room

- Line it with their regular bedding

- Sprinkle catnip or place treats inside to encourage exploration

2: Positive Association (Days 4-7)

- Serve meals near the stroller, gradually moving bowls inside

- Use interactive toys to create fun experiences

- Consider pheromone sprays to reduce anxiety

3: Movement Introduction (Days 8-14)

- Begin with stationary "sitting" in the stroller

- Progress to gentle rocking motions

- Eventually try short pushes across smooth floors

4: Outdoor Introduction (Week 3+)

- Choose quiet times (dawn/dusk)

- Start with brief 5-minute neighborhood walks

- Gradually increase duration based on comfort level

Critical Reminder: Never force a terrified cat. If signs of distress persist after 2-3 weeks, consider alternative enrichment methods.

Choosing the Perfect Cat Stroller: Buyer's Guide

Essential Features:

-

Escape-Proof Design - Look for double-zipper closures and secure latches

-

Proper Ventilation - Mesh panels should cover at least 50% of sides

-

Suspension System - Important for smooth rides on uneven surfaces

-

Weight Capacity - Ensure it can handle your cat's size plus any accessories

Top Recommended Models:

-

Cat Stroller Safety: Must-Know Tips

Do:

-

Always secure your cat with a harness as backup

-

Carry water and a collapsible bowl

-

Check pavement temperature before walks

-

Bring familiar-smelling items for comfort

Don't:

-

Leave your cat unattended (even "just for a minute")

-

Walk near busy roads or loud construction

-

Force continued use if your cat shows distress

-

Forget weather protection (rain covers/sun shades)

Safety Hack: Attach an AirTag or GPS tracker to the stroller for added security.

-

-

Alternatives for Stroller-Resistant Cats

-

If your feline friend rejects the stroller, try these options:

-

Harness Training - Best for confident cats (start with 15-minute indoor sessions)

-

Cat Backpacks - The enclosed space often feels safer to anxious felines

-

Catios - Outdoor enclosures provide fresh air without mobility stress

-

Window Perches - Simple solution for visual stimulation

Remember: Approximately 30% of cats never adapt to strollers - and that's okay! Indoor enrichment can be equally rewarding.

Final Thoughts: Is a Cat Stroller Right for You?

After working with hundreds of cat owners, I've found that success with strollers depends on:

-

Your Cat's Personality - Bold explorers adapt fastest

- Remember: Approximately 30% of cats never adapt to strollers - and that's okay! Indoor enrichment can be equally rewarding.

-

Final Thoughts: Is a Cat Stroller Right for You?

-

After working with hundreds of cat owners, I've found that success with strollers depends on:

-

Your Cat's Personality - Bold explorers adapt fastest

-

Proper Introduction - Rushing causes setbacks

-

Realistic Expectations - Not all cats will love it

For those who do take to strolling, the benefits are undeniable. One client reported her previously anxious cat became more confident after regular stroller outings, while another found it transformed vet visits from traumatic to tolerable.

Your Turn: Have you tried a cat stroller? Share your experiences below - what worked (or didn't) for your feline friend? For more cat care tips, check out our guide to indoor enrichment ideas!

-

-

Exploring the Best Materials for FDM 3D Printing A Comprehensive Guide

Fused Deposition Modeling (FDM) has become one of the most widely adopted 3D printing technologies. Known for its affordability and versatility, FDM allows users to create everything from simple prototypes to complex functional parts. One of the key factors in ensuring successful FDM printing is choosing the right material for your project. In this guide, we’ll explore the best materials available for FDM 3D printing and discuss their unique properties, applications, and benefits.

1. PLA (Polylactic Acid)

What it is: PLA is one of the most popular FDM materials, made from renewable plant-based sources such as corn starch. It’s an eco-friendly, biodegradable material.

Key Features:

- Easy to print with, especially for beginners.

- Low printing temperatures (around 190-220°C).

- Available in a variety of colors and finishes, including translucent options.

Applications:

- Prototyping for design and fit.

- Decorative objects and toys.

- Educational models and visual aids.

Benefits:

PLA is an excellent choice for simple, non-functional prototypes. It’s easy to use, produces smooth surface finishes, and has minimal warping.

Limitations:

PLA’s mechanical properties, such as strength and heat resistance, are lower than some other materials, which makes it unsuitable for parts that will endure high stress or temperature.

2. ABS (Acrylonitrile Butadiene Styrene)

What it is: ABS is a tough, impact-resistant plastic that’s widely used in manufacturing and prototyping. It’s the material used in Lego bricks, automotive parts, and various household appliances.

Key Features:

- High durability and impact resistance.

- Better heat resistance compared to PLA.

- Requires a heated print bed to prevent warping.

Applications:

- Functional prototypes.

- Automotive parts and enclosures.

- Mechanical components like gears and brackets.

Benefits:

ABS provides stronger, more durable parts that can handle higher temperatures and stress. It’s ideal for parts that need to endure daily wear and tear.

Limitations:

ABS can produce fumes during printing, so adequate ventilation is necessary. It also tends to warp if not printed on a heated bed, which can complicate the process.

3. PETG (Polyethylene Terephthalate Glycol)

What it is: PETG is a popular FDM filament that offers a balance of strength, durability, and ease of printing. It’s a modified version of PET, the same material used in plastic bottles.

Key Features:

- Excellent chemical resistance.

- High strength and flexibility.

- Less prone to warping compared to ABS.

Applications:

- Functional parts like containers, brackets, and tools.

- Parts requiring good impact resistance.

- Food-safe products (when using food-grade PETG).

Benefits:

PETG offers a good balance between ease of use and durability. It’s an ideal choice for parts that need to withstand chemical exposure or higher impact stress while being easy to print.

Limitations:

While PETG is relatively easy to print, it can be prone to stringing, which requires careful fine-tuning of print settings.

4. Nylon (Polyamide)

What it is: Nylon is a strong, durable, and versatile thermoplastic that’s used in a wide range of industries, including automotive and aerospace. It’s known for its excellent mechanical properties.

Key Features:

- High strength, flexibility, and wear resistance.

- Excellent for making functional, durable parts.

- Hygroscopic (absorbs moisture), so proper storage is essential.

Applications:

- Mechanical parts like gears, bearings, and moving components.

- Prototypes that require high strength and flexibility.

- Industrial-grade applications in automotive and aerospace.

Benefits:

Nylon’s strength and wear resistance make it ideal for parts subjected to heavy use or stress. It also offers a great balance between flexibility and durability.

Limitations:

Nylon is hygroscopic, meaning it absorbs moisture from the air, which can affect print quality. It’s essential to keep the filament dry during storage and use.

5. Polycarbonate (PC)

What it is: Polycarbonate is a high-performance plastic that’s known for its toughness, impact resistance, and high heat resistance.

Key Features:

- Exceptional impact strength and durability.

- High heat resistance (up to 120°C or more).

- Can be transparent, offering optical clarity.

Applications:

- Aerospace and automotive parts.

- Functional prototypes that require high strength and heat resistance.

- Protective covers, lighting, and lenses.

Benefits:

Polycarbonate is ideal for parts that need to endure extreme conditions, including high stress, heat, and impact. It’s also one of the clearest 3D printing materials available.

Limitations:

Polycarbonate requires a heated bed and an enclosed print environment to prevent warping. It also requires a high printing temperature, which may not be compatible with all 3D printers.

Conclusion: Choosing the Right FDM Material for Your Project

FDM 3D printing offers a variety of materials, each with unique properties suited to different applications. Whether you need a simple prototype, flexible parts, or durable, high-performance components, understanding the strengths and limitations of each material will help you make the right choice. At YYI TECH, we offer a range of FDM printing services to bring your ideas to life using the best materials for your needs.

Explore the potential of FDM 3D printing and choose the right material for your next project—get in touch with us today to start printing!

...

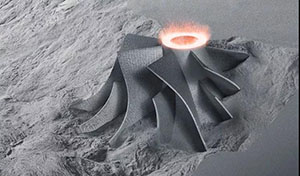

Harnessing SLM Technology for Automotive Metal Intake and Exhaust Cones

In the ever-evolving automotive industry, the demand for high-performance, lightweight, and durable components continues to rise. One area where innovation is making significant strides is in the manufacturing of metal intake and exhaust cones. Selective Laser Melting (SLM) technology is at the forefront of this revolution, offering unparalleled advantages in producing these critical components. In this article, we explore how SLM technology is transforming the way SLM Car inlet and outlet cone are designed and manufactured.

What is SLM Technology?

Selective Laser Melting (SLM) is an advanced additive manufacturing process that uses a high-powered laser to fuse metal powder into solid parts. This technology builds components layer by layer, allowing for intricate designs and complex geometries that are difficult or impossible to achieve with traditional manufacturing methods.

Applications of SLM in oem Automotive Metal Intake and Exhaust Cones:

1. Complex Geometrical Designs

Automotive intake and exhaust cones often feature intricate geometries to optimize airflow and enhance engine performance. SLM technology excels in producing these complex shapes without the need for additional tooling or machining. This capability allows for greater design freedom and the creation of components that are both efficient and effective.

2. High-Performance Materials

SLM technology can utilize a variety of high-performance materials such as aluminum alloys, titanium alloys, stainless steel, and nickel-based superalloys. These materials provide excellent strength-to-weight ratios, corrosion resistance, and high-temperature performance, which are critical for components exposed to extreme conditions in the engine and exhaust systems.

3. Lightweight Design

One of the key benefits of SLM technology is its ability to produce lightweight components without compromising strength or durability. By using topology optimization and advanced design techniques, manufacturers can reduce the weight of intake and exhaust cones, leading to improved vehicle performance, fuel efficiency, and reduced emissions.

4. Rapid Prototyping and Small Batch Production

SLM technology enables rapid prototyping and small batch production, making it ideal for developing new designs and testing concepts. This agility allows automotive manufacturers to iterate quickly, refine designs, and bring innovative products to market faster than ever before.

5. Enhanced Durability and Longevity

Components produced using SLM technology exhibit superior mechanical properties, including high density, fatigue resistance, and thermal stability. This results in intake and exhaust cones that can withstand harsh operating conditions, ensuring long-term reliability and performance.

6. Custom Cooling Channels

SLM technology allows for the integration of custom cooling channels within the intake and exhaust cones. These channels help manage thermal loads more effectively, reducing the risk of overheating and improving the overall efficiency and lifespan of the components.

Real-World Applications

1.Turbocharger Components

SLM technology is used to manufacture lightweight and high-strength intake and exhaust cones for turbochargers. These components optimize airflow and enhance engine performance while withstanding

high temperatures and pressures.

2. Exhaust Systems

In high-performance and racing vehicles, SLM-produced exhaust cones offer superior durability and reduced weight, contributing to better handling and acceleration.

3. Custom Automotive Solutions

For custom and prototype vehicles, SLM technology provides the flexibility to create bespoke intake and exhaust cones tailored to specific performance requirements and design preferences.

SLM technology is revolutionizing the production of automotive metal intake and exhaust cones, offering unparalleled advantages in design, material performance, and manufacturing efficiency. By leveraging SLM, automotive manufacturers can create high-performance, lightweight, and durable components that meet the demands of modern vehicles.

At Dongguan YYI Technology, we specialize in using SLM technology to deliver top-quality automotive components. Contact us today to learn how our SLM solutions can benefit your next project and drive your innovation forward.

...